Custom Rigid Boxes

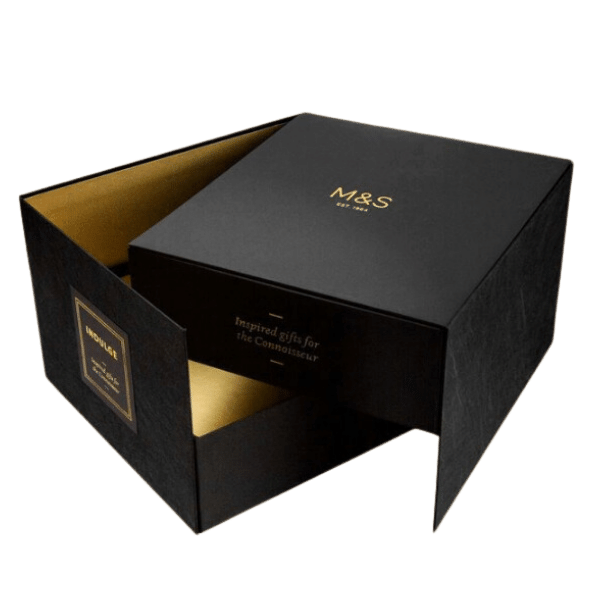

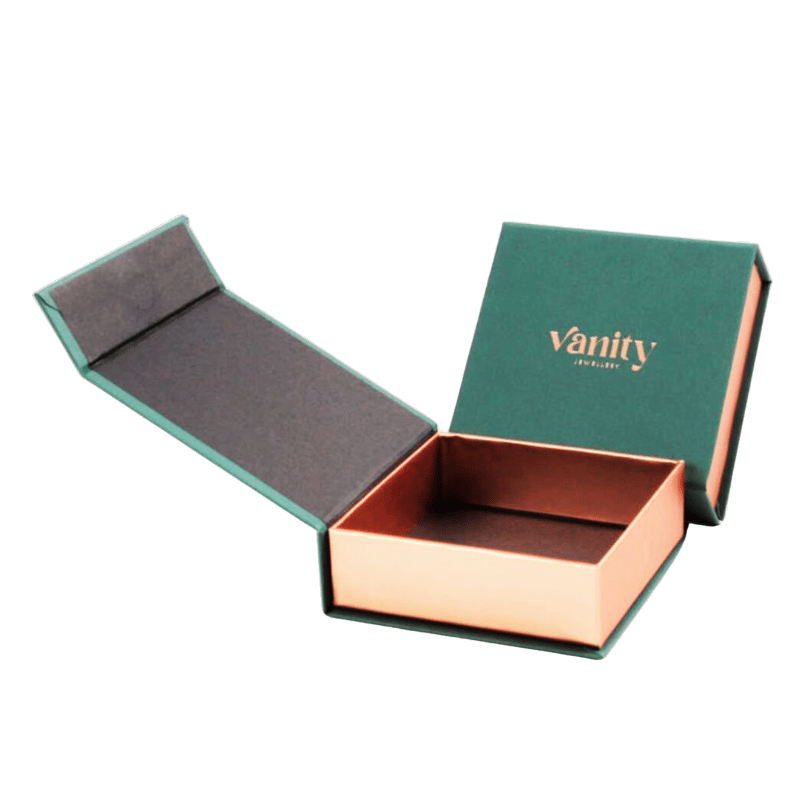

A rigid box is a perfect packaging solution for high-end or luxury products. These boxes are made from thick Paperboard for the ultimate protection of your products. Two types of rigid boxes are available: two-piece rigid boxes with a separate lid and base or one-piece magnetic rigid boxes. You may find additional inspiration by reviewing examples of gift set packaging.

RIGID BOXES CAN BE CUSTOMIZED TO FIT YOUR NEEDS

Custom rigid boxes can provide your Company with a significant competitive advantage. A wide range of high-end functionality boxes are available from CUSTOM BOXES NEAR ME to benefit your organization in several ways. Various rigid boxes with lids are available, including rigid telescopic boxes, rigid shoulders and neck boxes, flip boxes, and magnetic closure boxes.

The best option for you will depend on your requirements. Are you having difficulty making a decision? Our graphic designers will assist you throughout the process. Our innovative die-cutting equipment produces crisp and precise edges on your boxes, making them more convenient.

Wholesale rigid gift boxes

The Perfect Rigid Box - Innovatively Designed

Our goal at CUSTOM BOXES NEAR ME is to provide you with a wide range of options for enhancing the appeal of your product. Our wholesale rigid boxes come in a variety of styles. The rigid box type ranges from two-piece luxury rigid box packaging to rigid lid boxes to custom-printed rigid boxes with magnetic closures. Further enhancements can be added to the boxes by adding PVC windows and die-cutting. Additionally, our printing designs are alluring with eye-catching text, making them ideal for packaging. Design, style, size,

and shape are all available in various options. You may choose anything from our range of products and modify it according to your requirements. Using UV coatings, debossing and embossing, and lamination, you can enhance the appearance of your custom-printed boxes.

How do rigid boxes or setup boxes work?

Custom rigid boxes consist of high-quality (often 2-3mm thick) chipboard covered in decorative speciality paper. Due to their luxurious appearance and feel, they are commonly referred to as setup boxes or premium packaging. This type of packaging is suitable for items such as board games, luxury goods such as jewellery, or gifts.

Furthermore, these custom boxes provide a premium feel that enhances the unboxing experience for your customers, allowing for more opportunities to establish a strong brand narrative. Through its printing and finishing capabilities, it can provide many branding capabilities, including;

- Embossing/debossing

- Hot stamping

- Decorative elements

- Coatings

Differences between flexible, corrugated, folding cartons and custom rigid boxes

You may have heard of other options, such as flexible packaging, corrugated boxes, and folding cartons if you have researched and read about the other types of packaging that may suit your product. Flexible and rigid cartons can be distinguished by their names, but corrugated and folding cartons may be more difficult. Let us briefly discuss each option and how they differ to ensure we cover all our bases.

For starters, rigid boxes are constructed and supported with sturdy materials and are comparatively more luxurious. Unlike flexible packaging, these trending packaging options consist of thick chipboards and need to change shape more easily.

It is more difficult, however, to differentiate between the other options since they are very similar. As rigid boxes are considered superior in presentation, folding carton boxes and high-end corrugated packaging are popular alternatives due to their cost-efficiency and versatility in high-quality printing and finishing. Here are some differences;

Based on the above chart, you can see that the options are similar, and it is entirely up to you to decide which packaging solution to use. Please read more here for more information about folding cartons and corrugated packaging. We can proceed if you are confident that this option meets your needs.

Rigid packaging types

Custom rigid boxes are available in two finishes: partial and full.

Partial finishes are those in which the wrapping and chipboard have only been partially completed. In contrast to the wrap, the chipboard is left exposed and bare on the outside of the box. Boxes with partial finishes use a single chipboard with perforated crease lines, exposing the kraft or grey chipboard underneath.

Due to the fewer materials required in the construction process, this option takes much less time to produce.

The full finish, on the other hand, leaves no exposed chipboard; the wrapping covers the entire box. Alternatively, you can use a thicker chipboard of 2-3 mm and separate the inner chipboard for each side of the box. Various finishing options are also available for lamination.

Packaging with a full finish also includes an additional layer of wrapping, either white by default or printed.

Partial Finish:

Only the inner edge of the boxes is wrapped

There is visible unfinished chipboard inside

There are perforations in the crease lines and folds of the internal chipboard.

The chipboard may be taped before it is wrapped if desired

There are two types of chipboard finishes: white and kraft.

Full Finish:

Completely wrapped. Chipboard is not exposed

Each face of the box is made up of a separate piece of chipboard

Before wrapping boxes, there is no tape

2 mm – 3 mm thick chipboard (or greyboard)

Various finishing options are available when laminating

What is the manufacturing process?

How do rigid boxes reach this finished state? To simplify the process, we have divided the construction of one of these high-end boxes into four simple steps:

Box size – The box is constructed from a flat paperboard that is first cut and scored to the proper size.

Folding – Once the Paperboard is folded, it is secured with tape to form the box’s base.

The wrap is printed and laminated with a design. The addition of other add-ons is at your discretion. It is then glued to the shape of the box.

Wrapping – Your box is tightly wrapped, and we are done!

To help you better understand the process of completing your box, please refer to the following figures:

Style-Complementing Inserts

Choosing rigid boxes can be challenging, but once you have selected the type you prefer, the next step is to consider what inserts will go inside.

Additional packaging materials like box inserts are very popular when designing rigid packaging. For the best unboxing experience, packaging inserts are highly recommended.

It offers high shock protection, even against drops and rough handling, while providing an elevated presentation. These custom packaging inserts are made specifically for your product.

Most commonly, custom inserts are made of;

- Plastic

- Foam

- Paperboard

- Molded pulp

- Corrugated

Is that right for you? Rigid boxes: pros and cons

Having discussed all the available design options, why should you select this option? Additionally, rigid packaging offers a unique look and feel unmatched by most other types of packaging, in addition to its solid and protective construction.

The packaging solution is often paired with a custom insert to ensure products are well-protected against harsh handling. This packaging is even designed to be reusable and kept by the customer rather than thrown away following the unboxing of the product.

As a result of these benefits, rigid packaging boxes add significant value to your brand by embedding an embedded element that complements your product. With a rigid box, your product is no longer perceived as a single item but rather as a set when presented to your customers.

As a rule, people enjoy receiving gifts, and rigid gift boxes are currently the gold standard of gift packaging. There are, however, certain disadvantages associated with any packaging.

Despite their excellent performance for small to medium-sized products, these packaging options have a surprisingly low level of resilience when applied to extra-large products. As the outer layer of the wrapping paper becomes more loaded at larger sizes, edges are more prone to ripping, To increase the durability of wrapping paper, thicker wrapping paper with a laminated finish is always recommended.

One of the biggest disadvantages of high-end, custom rigid boxes is their high price. The cost of making one of these boxes is high.

This type of packaging is unlike any other type of packaging. As with wrapping a gift, rigid boxes are constructed by precisely wrapping paper around solid boards. It may take 1-2 weeks longer to produce these boxes because each chipboard is individually glued together.

Most production processes for this type of packaging involve manual assembly and detailed quality checks to ensure that defects are not present and quality standards are met. Therefore, it can be up to three times more expensive than folded cartons and corrugated packaging.

We understand that many smaller companies face budget constraints despite the higher price being readily justifiable to more prominent brands because luxury packaging adds tremendous value to both the product and the brand. To learn how to cut costs for rigid boxes and other options, please check out our other article on creating affordable luxury packaging.

What makes Custom Boxes Near Me a good choice?

It is common to use custom rigid boxes during festive holidays. During different festivals, you can use them to present your products for seasonal promotions. A great deal of care is taken with the design of rigid boxes. We continuously develop unique box theme ideas to reflect the type of occasion, whether it be a new product launch, a tradeshow, or a corporate event. We provide all services. You can find the best custom rigid boxes for your brand with us. Are you interested in the look and quality of the rigid boxes? Order a pre-printed rigid box sample to better understand the materials and printing options we use during manufacturing. You are satisfied with the quality of the box printing. It is time to request a custom quotation for your custom rigid boxes in no minimum quantity to present your products professionally. Box orders are not limited; you may order starting as low as one box without any minimum order quantity.

Would you like your rigid boxes delivered directly to your home, office, or fulfilment centre? We are happy to assist you. Let us handle your deliveries within the timeline we have promised. Our certified quality assurance and quality control departments ensure that our packaging services are high quality and error-free in all states of the United Kingdom. Our primary concern at Custom Boxes Near Me is to fulfil your packaging needs. To order your desired boxes, please call us at 7438879019 or send an email to sale@customboxesnearme.co.uk

Rigid Boxes Frequently Asked Questions

1. Create some templates (I made my own by printing pictures on standard A4 printer paper).

2. Remove all black lines from your templates.

3. Follow all grey lines when folding.

4. Attach the parts of the box where they belong by glueing them together.

5. If you wish to prevent your folds from shifting when you have applied glue, make a small slit in each fold with your knife or scissors.

6. Apply some glue to every fold, and fold the box back so that all sides have a neat edge.

To choose the right luxury rigid box manufacturer, you must understand your requirements. There will likely be at least one rigid luxury box manufacturer out there that will meet all your expectations if you already have experience with rigid luxury box manufacturers. If you still need to, you should conduct further research to narrow your options and choose only the most appropriate products. Doing this will save time and money, as you will only spend your time and money on a luxury rigid box manufacturer that meets your expectations.

The rigid gift boxes are uniformly sized packages used for safely transporting presents and other fragile items without causing damage. Additionally, buyers may use these services to ship their items. With a rigid box, you can find the right size much easier since it has a uniform, flat shape. Various sizes are available, as well as printed paper or stickers that can be customized. The advantage of rigid boxes is that they have stronger walls, so even if you handle them roughly while transporting the package from your doorstep to the recipient’s doorstep, you won’t have to worry about denting them. It can be quite challenging if you need to know what you are looking for when purchasing rigid gift boxes.

Sellers usually use rigid gift boxes to transport their products safely from one place to another. Aside from that, since they have flat walls, it is relatively easy to fill them up, as long as the item you are trying to place in there fits inside. No matter how full your box is, your item will remain snug and secure. As a result, they are ideally suited for people who wish to sell their products or items that would not fit into a soft gift box, such as extra-large pillows or bean bags. Using rigid gift boxes as packaging gives you greater protection than simply placing your items in a shipping envelope. It prevents your package from being crushed by other products on the conveyor belt (should you be selling in large quantities).

Rigid Gift Box- Large

Various colours and ratios are available, but this is the most common and popular. The dimensions of this size box are 15 1/8″ x 12 7/8″ x 5 3/8″. A maximum depth of 12 1/4″, a maximum width of 10 1/2″, and a maximum height of 5 3/4″ are possible with this container.

Small rigid gift box

You should also be aware of the smaller rigid gift boxes with dimensions of 9 112 inches by 4 344 inches by 2 128 inches. This size is ideal for shipping jewellery, clothes, or anything else that requires a large amount of space.”

The material of rigid gift boxes may vary, but they usually weigh between 30 and 50 pounds. This box type is made of high-density cardboard, known as corrugated fiberboard, one of the most durable materials. This special type of paper has been pressed together and glued with wax. Due to its unique layers, it can be bent easily without getting damaged or dented too much. It is perfect for shipping items because you want to protect them from damage.

It is possible to make rigid carton boxes by folding corrugated sheets, usually made from. There may have been an addition of recycled fibre board containing 5% to 30% recycled content. Various printing techniques are used to print cartons, including flexography, gravure, letterpress seals, and metalizing. It is becoming increasingly common to use Flexo printing, which prints four colours simultaneously with two flexo-printing plates. Ceramics are also subjected to this method.

Custom rigid boxes are constructed of cardboard stiffened on all surfaces except the top. Boxes of this type are constructed from corrugated boards with at least two flutes in combination with solid cardboard. Rigid boxes are also characterized by their strength, which ensures safe transportation by protecting the contents from shocks and vibrations. While the ribs allow the carton to expand when filled, they will not bend under pressure, as would be the case with an ordinary carton. If a cutout is made on one of the sides, it will not tear out even when the maximum force is applied.

First, when choosing a supplier of rigid boxes or any other type of packaging, you should use your intuition and robust factual information. You might be tempted to buy from your suppliers when they provide an estimate. However, you should be bold and walk away if you need clarification on their competence. Luxury rigid boxes are what they sound like. One of the most prominent types of boxes is the luxury rigid box. There are many different kinds of boxes, each with a different size and shape. There is usually a specific design for these types of boxes, and they are typically constructed from high-quality materials. These boxes can add an extra touch of elegance to your gift packaging when you intend to buy a small gift for someone special in your life.

For shipping a wide variety of items, rigid boxes are the most common type of packaging. Rigid boxes are commonly found in the packaging of shoes, printer paper, and pizza deliveries. A particular shipment’s size, shape, and strength determine box types. To store long, narrow objects, such as books or CDs, tall, thin boxes with little depth must be stacked vertically without taking up excessive space.